“An electric car? No thanks, especially if it means hanging around while it charges.” quips Pimpmyride1 on an on-line auto forum, to which Supercar-59 adds, “EVs lack punch!”. It is time these misconceptions are done away with. Indeed, the time when EVs had to be plugged in every 100km is over. Yes, there are more and more charging stations (on public roads, but also in businesses and at homes). No, electric cars do not suffer more from the cold than combustion engines. And, yes, the carbon footprint of an electric vehicle is actually lower than that of a combustion motor over its entire life cycle. Not to forget that it’s a joy to drive. The difference is immediately perceptible: electric cars offer a fast and quiet start, with instant torque needed for clean and powerful acceleration. Being behind the wheel of an electric car is like crouching into a tuck to swiftly speed down a ski slope. So yes, EVs do pack a punch.

Because e-mobility comes with all these advantages – and then some – it is quite clearly a solution for the future. On one condition: that it is supported by a responsible and sustainable value chain.

1. Renault Group: a pioneering vision

Still have doubts? We don’t.

Generations of engineers have spent the past 15 years developing our EV models, while procurement teams have been trained up over the past 10 years and our dealerships know EV inside out: everyone is pitch perfect and ready to go. In fact, all our European manufacturing sites are converting over into EV production plants. We have believed in the future of electric vehicles for more than a decade. Ten years during which we have boldly designed models for any use imaginable.

And when look back over our past in the rear-view mirror, there’s much to be proud of:

- more than 400,000 customers worldwide

- more than 10 billion e-km travelled

- 30,000 RG employees with specific EV training

We are stepping up efforts to win over those who still need a bit more convincing: by bringing innovation to our customers, designing increasingly efficient and accessible electric vehicles, and developing large-scale, sustainable electrical ecosystems.

2. Safe, powerful and affordable batteries

Batteries are the beating heart of electric cars and are the focal point for our engineering teams.

To optimize both their cost and performance, we will adopt a new approach in 2024: standardization.

Standardization in terms of the physical structure because all our batteries will be made using only two cell formats, but also in terms of chemistry since we use NMC type lithium-ion batteries.

If you’re still not entirely up to speed with the ins and outs of Li-NMC technology (NMC, a.k.a ‘Nickel, Manganese, Cobalt’), here’s a quick video to help:

The two cell formats are as follows:

- an affordable design with excellent cost-to-battery-life ratio for A- and B-segment models, made in the ElectriCity Gigafactory (that we will discuss later);

- and a high-performance solution with fast-charging capacity for C-segment and sports vehicles.

Curious to know more about how batteries work? Find out everything you need to know to make a good impression.

Another major topic when it comes to batteries is safety. In this regard, we can confidently say that Renault has set industry-wide standards, with thermal runaway not once being reported over the last ten years.

This is partly thanks to the roll out of Renault’s own ‘Battery Management System’ – a battery monitoring system fitted on our vehicles – that prevents rising battery temperatures and thus reduces the risk of internal fire. It is also thanks to innovative security measures such as the Fireman Access – an incredibly effective way for rescue teams to quickly and permanently extinguish battery fires caused by an external fire. Not to forget the ‘Rescue Code’ (a QR code located on the wind shield) that gives fire-fighters easy access to documentation on the battery’s technical specs.

To find out more, (re)discover:

- Episode 2 of keynotes on batteries

- The press release “Renault Group places France at the heart of its industrial strategy for EV batteries”

3. A state-of-the-art powertrain

Now let’s talk E-engines. With ten years of experience in E-engine technology, we harness the power of electrically excited synchronous motors. Why is that? Mainly because it has key advantages such as excellent power yield (better than permanent-magnet synchronous motors) and it doesn’t incorporate rare earth metals (thus making it cheaper with large-scale production).

Proven technology with exciting prospects: the next generation of electrically excited synchronous motors will be able to handle the higher 800V power supply, and will incorporate state-of-the-art technology making it safer, smaller, and more efficient.

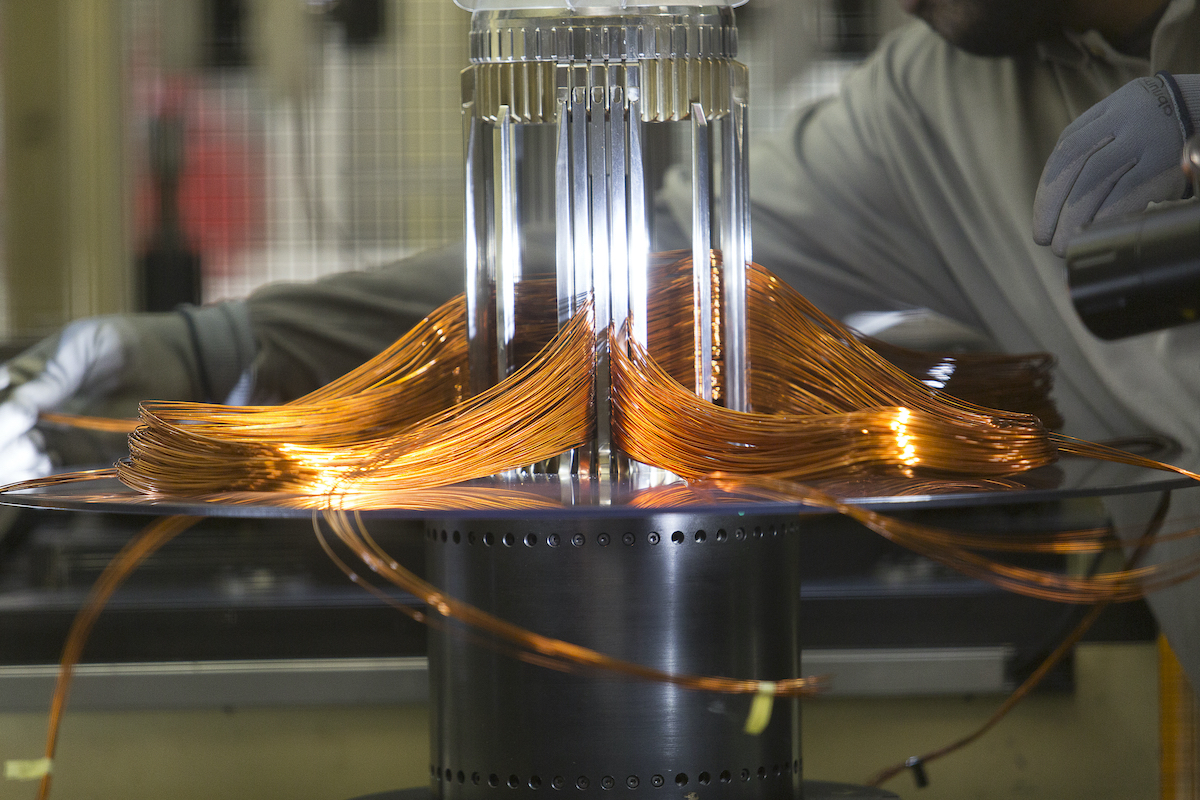

As the adage goes, a picture is worth a thousand words: here is our upcoming electrically excited synchronous motor:

As for power electronics – still as part of our quest for greater efficiency – we are working on a new strategy with three primary objectives: reduce electricity loss, cost, and size. This will be achieved thanks to our ‘One Box’ concept whereby all power electronics (reducer, DC-to-DC converter, on-board charger) will be mounted inside a single unit.

Another strategic goal is to vertically integrate power electronics to have greater control over both costs and the value chain. More specifically, we will start off by developing advanced expertise in electronics design, followed by a second phase where we will internalize printed circuit board assembly.

We have been discussing innovation in both electric motors and power electronics. Two essential parts of a much larger ensemble: the vehicle’s overall powertrain. We are working on a fully integrated power train with the electrically excited synchronous motor, reducer, and One Box power electronics all combined into a 3-in-1 system.

45% less electricity loss

(for a 20km increase in range)

30% lower costs

40% smallergiving more room for passengers

We will take things yet another step further with the addition of disruptive technology: the axial flux motor. Developed in partnership with French start-up Whylot, it will boast numerous advantages for our hybrid vehicles, such as a 5% cost reduction, and CO2 gains of up to 2.5 grams. Benefits that will trickle over into our EV range.

This investment will see us become the leading automotive parts supplier for these electric motors as of 2025.

4. The best tech around on our platforms

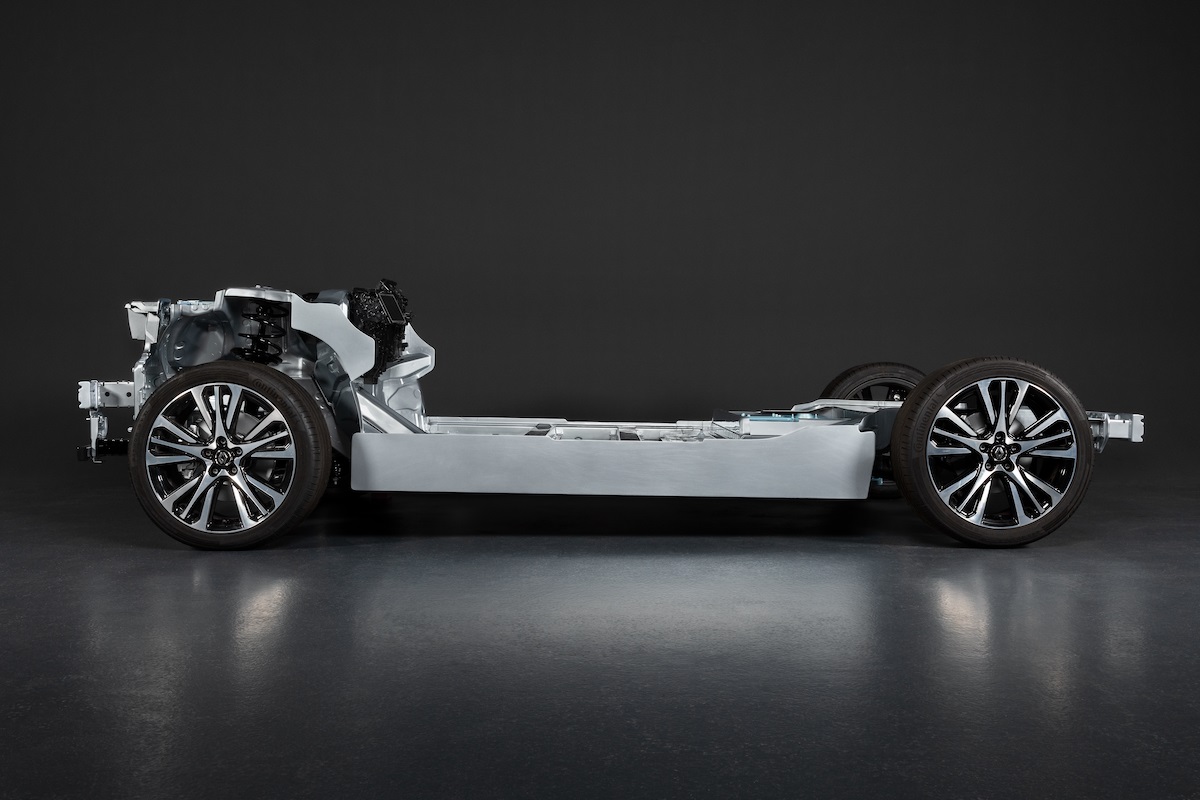

To accommodate high-performance, bespoke batteries and a particularly efficient and compact power train: we use state-of-the-art EV platforms. Platforms that house each piece of tech you have just glimpsed.

Platforms that come in one of two versions:

- ‘CMF-EV’ for C/D segment vehicles, such as the All-New Megane E-TECH Electric, for even more driving pleasure

- ‘CMF-BEV’ for segment B vehicles, such as upcoming Electric Renault 5, for the best price-to-performance ratio possible.

Let’s take a closer look at each platforms to better grasp how they make for a much smoother drive.

CMF-EV platform:

- Advantage #1: Autonomy

Vehicles based on the CMF-EV platform will boast a WLTP range of up to 580 km, thanks to optimized efficiency and energy management.

Just how have we achieved that? We have worked on reducing friction and weight (-100kg compared to the closest competitor model) and improving thermal management (+5% range in cold weather), in addition to incorporating our battery technology (e.g., NMC technology).

- Advantage #2: Comfort and driving pleasure

Gliding through the countryside behind the wheel of an electric car may already seem like a truly enjoyable experience. But now imaging gliding along those same roads in a church-like silence. This is the principle behind the ‘smart cocoon effect’ which harnesses the power of patented soundproofing foam placed between the battery and the floor plate to reduce in-car noise by 50% compared to current models. The foam also creates a sound barrier against the wind and road.

The passenger compartment is quitter, but also roomier. Our ‘smart packaging’ means more leg room and more luggage space, putting it on par with larger vehicles. It also features excellent ergonomics with a particularly comfortable sitting position and a comfortable rear leg room. Why is that? Simply put, all powertrain components are placed in the front end, thereby helping to give more room and reduce both overall weight and cost. Not to forget that the heating, ventilation, and air conditioning system is mounted under the bonnet, which means the dashboard isn’t as deep giving more room for passengers. Lastly, the battery pack, among the slimmest for the specific drive range, leaves more room between the floor plate and roof.

One last point on ‘comfort’, our vehicles are now more enjoyable to drive thanks to optimised on-road dynamics:

- the very low steering ratio means faster response, better handling, and greater agility

- the multi-link rear suspension means better road-type adaptation and wheel alignment

- the battery’s position in the vehicle makes for a lower centre of gravity and ideal weight distribution

CMF-BEV platform

- Advantage #1: Cost

The first and perhaps most anticipated advantage of our second platform is the 33% reduction in the overall cost of vehicles (compared to ZOE), which has been made possible thanks to:

– an interchangeable battery module for cross-platform use

– a new and smaller powertrain for cheaper output at 100kWh

– the use of ‘non-EV’ CMF-B platform components on the platform and upper body, which means a significant drop in the costs of parts

- Advantage #2: Versatility

The remarkable features of this platform are achieved without compromising on its design: the platform has been optimized to be highly versatile and easy to adapt to all sorts of vehicles, including our most iconic models.

5. Renault ElectriCity: the best industry-side EV solutions

State-of-the-art platforms, batteries, and power trains for EV models that are more efficient than ever. As we put our EV vision into motion, we strive for greatness in the Renault ElectriCity. A unique industrial hub like no other in Europe and a centre for Alliance excellence that brings together three of our facilities: Douai, Maubeuge, and Ruitz. It also incorporates an entire ecosystem of contractors – including an EV battery ‘Gigafactory’.

Why is the ‘EV Hub’ in the north of France? Because in manufacturing out of such a strategic location – in the heart of Europe – we will reduce the cost of logistics for foreign customers.

The project is driven by two main ambitions: stimulate innovation and efficiency; and reduce production costs by building on Renault’s industrial expertise, in particular by leveraging the power of flexible assembly lines that can produce two platforms and by pooling together indirect functions across the three plants.

With a projected output of 400,000 vehicles per year, Renault ElectriCity will be the leading and most competitive production centre in Europe! The life blood of our ambitious project, 700 direct jobs that will be created by 2025, and spread across the three factories in Maubeuge, Douai, and Ruitz. In addition, a tertiary education centre will be set up in the near future to provide training programmes that are adapted to the changing automotive market and to help further research.

Find out all there is to know on the subject:

6. Batteries that will last many lifetimes

So far, we have discussed the driving pleasure, performance, and range of our electric vehicles. Now comes the issue of sustainability; in particular, when it comes to batteries. Once again, we have good news that will shake up a few preconceived ideas: batteries outlive the cars they power. Because, just like cats, batteries have many lives. And we will be there at every step of the way – in other words, throughout their whole ‘life cycle’ – to make sure our vehicles are as profitable and affordable as possible. Let’s explain how.

1st life:

What purpose does a battery serve in an electric car? First and foremost, to drive the car. But did you know that during a battery’s first life – while it’s still in a car – it can also be used to provide cities, buildings, and homes with electricity during peak power consumption? This is known as vehicle-to-grid (V2G). Grid operators are ready and willing to pay for services provided by car batteries that can reinject energy back into the grid for 8 hours a day: up to 400€ per year and per car.

In this regard, Renault is ahead of the curve and is developing large-scale V2G services ready for 2024, including a fully integrated Europe-wide service and a proprietary solution for bi-directional AC charging (less expensive than its DC equivalent). In addition to its smart off-peak charging solution, Renault will be rolling out V2G services in the near future.

Learn all there is to know about V2G in under 2 minutes:

2nd life:

Our batteries are built to last about ten years. But even after having powered your car for all those years, they still have energy to burn during retirement (a.k.a. ‘2nd life’). Their new purpose in life: to provide electricity to a less ‘energy intensive’ system or to serve as a stationary storage unit. Here again, Renault is shaping a market that will boost the residual value of batteries. How? By developing an industrial ecosystem that is like no other in Europe: a used battery collection network, a re-factory in Flins, and a range of industrial partnerships that cover the wide selection of new purposes for used batteries.

Aside from the ecological argument behind reusing second-hand batteries for stationary energy storage, it also helps drive further value creation. Renault, through Mobilize, will also work with Argus – among others – to widely promote the residual value of EV batteries, so that it can be properly reflected in the sale and purchase of used vehicles. Residual value can reach €500 per car.

Recycling:

When a battery reaches the end of its 2nd ‘plentiful’ life (between 5 and 10 years), it then enters the world of recycling. The ‘downstream’ processes of the recycling industry are already well mastered, with the collection of batteries and their dismantling in Flins. What if tomorrow we could go further by reconstructing new batteries from end-of-life batteries? This is the ambition we have set ourselves with other major industrial groups, Veolia and Solvay. By uniting our forces, we will extract, separate, and purify metals such as lithium, nickel, or cobalt, so that they can be reused in new batteries. That brings us back to where we started.

Here, too, beyond the obvious ecological importance, we will be able to leverage the value of this process: it will not only allow us to recover more valuable materials, but also halve the net cost of recycling by 2030.

7. The future is electric: 10 new models join the ranks

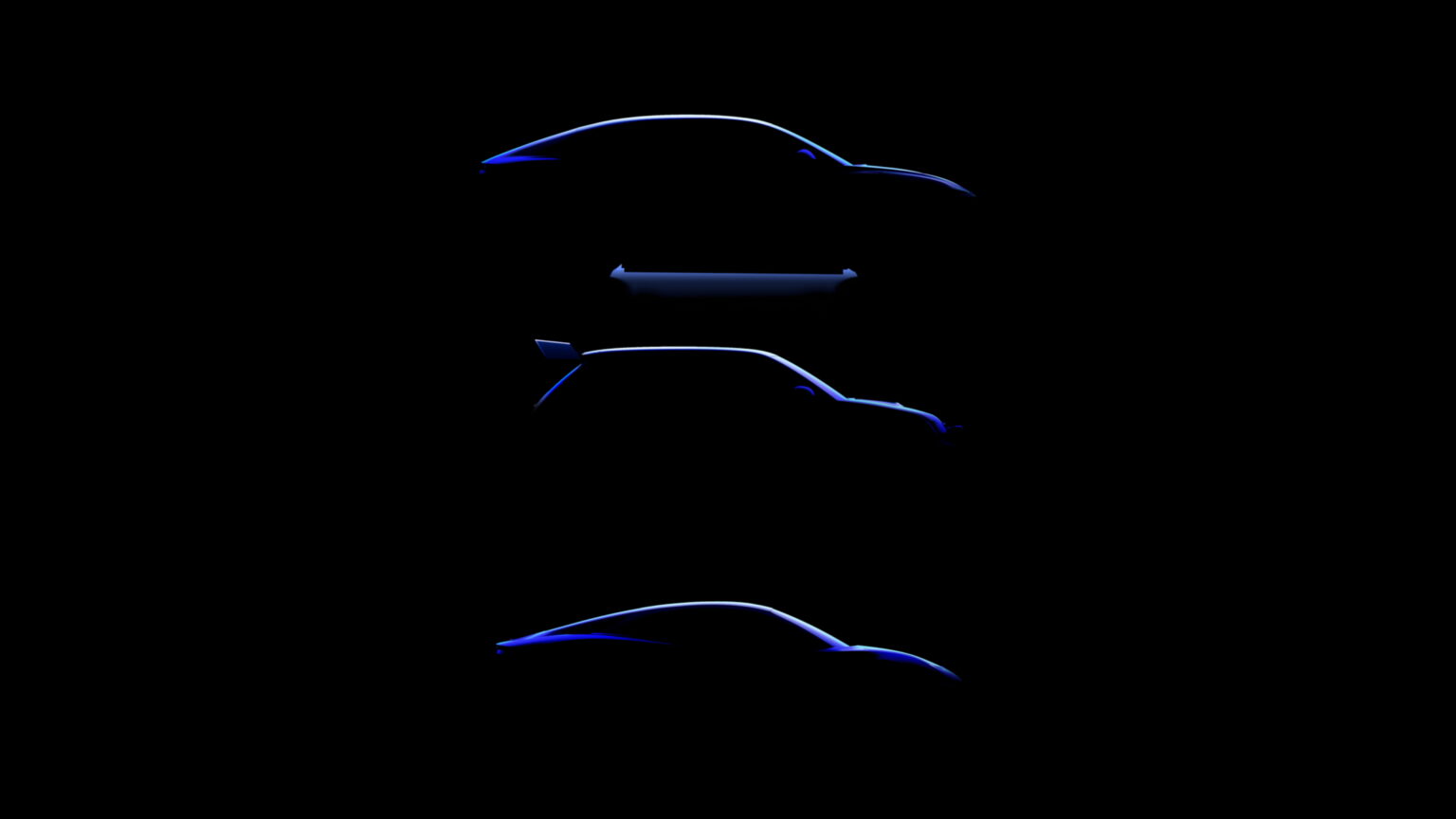

It has been made quite clear that we are already well positioned for the future of electric mobility. In fact, our family is set to grow in the next five years with 10 new models.

You may have already seen the show cars that will give rise to our first two models: Megane eVision, a powerful EV sedan with a bold design and leveraging everything the CMF-EV modular platform has to offer; the legendary Renault 5 EV, built on the CMF-BEV platform, will bring together an iconic design with a powerful yet affordable vehicle. Megane eVision will become the All-New Megane E-TECH Electric in just a few months, and the R5 EV will hit the market in 2023.

Seven more models from the Alpine and Renault ranges will round out the new additions, with – you have probably already guessed it – a new take on one of our legendary models. While you will need to be patient before you get to sit behind the wheel of one of our new models, know that they will all share a defining feature: excellent price-to-performance ratio without compromising on design.

The All-new Mégane E-TECH Electric will soon be accompanied by another model on the CMF-EV platform

After the R5, another Renault icon will return in a 100% electric version on the CMF-BEV platform

Alpine’s 100% electric “Dream Garage” will soon be a reality

“In the nineties, electro music was a big hit in France. It gave birth to the ‘French Touch’ with iconic bands. Electro Pop is the ‘Renault touch’ of electrification. We aim for iconic cars, making it to the top of the charts.”

Luca de Meo, CEO Renault Group

Beyond accessibility, and innovative technology and design, we endeavour for our future range to be the greenest mix of cars on the European market by 2025, with up to 90% of Renault sales coming from EV models. The future will be electric, and it will be clean.