Here are some highlights of the technology offensive that the Group has led over the past year:

Launch of the Refactory – Europe’s first factory entirely dedicated to the circular economy

Last year, Renault Group announced that it was transforming the Flins site into a factory dedicated to the circular economy. A first in Europe. With the Re-Factory, Renault Group is reinventing itself to develop accessible, sustainable, carbon-free mobility solutions for everyone.

To know more click here.

Creation of Hyvia – a joint venture dedicated to hydrogen mobility

Where does HYVIA come from? From the contraction between HY for hydrogen and VIA from the Latin for road.

HYVIA is a family of 50 employees with plenty of motivation to share around, excited to tackle the challenges of hydrogen-powered green mobility. The teams are animated around projects that embody their desire to have a positive impact on the energy transition to open up an alternative path to low-carbon mobility. The ambitious objective of this joint venture, which was born from the meeting of Renault Group and Plug Power, is to achieve a 30% market share in the hydrogen Light Commercial Vehicle market by 2030.

To know more click here.

Creation of the Software République – a new ecosystem that aims to innovate in intelligent and sustainable mobility

At the heart of this unique project in the sector: leading companies – Atos, Dassault, ST Microelectronics, Thales & Renault Group – and innovative start-ups united to create mobility solutions and systems that will shape the (near) future of mobility.

To know more click here.

Partnership with Google Cloud to meet the challenge of a decarbonized industry

Renault Group has joined forces with Google Cloud to accelerate the transition to carbon neutrality in the automotive sector. Renault is contributing its experience as a manufacturer, and Google Cloud its technological know-how. A concrete example of open innovation!

To know more click here.

The consortium between Renault Group, Veolia & Solvay

The three partners join forces to recycle end-of-life EV battery metals in a closed loop. The aim is to preserve resources, reduce carbon emissions and create value.

Renault Group is the first carmaker to act on the entire life cycle of the battery.

To know more click here.

The industrial Renaulution

Industrial Renaulution is underway. This Renaulution is driven by the expertise of the Women and Men of the Renault Group Industry, who are committed to performance, value creation and sustainable production.

2021, a year of transformation for the Group

Both at the strategic level…

With its Renaulution strategic plan, Renault Group has a clear ambition: to move from volume to value while repositioning its brands, each with a strong identity.

Renault – the Group’s historic brand on track for “La nouvelle Vague”.

Renault is moving towards an even more competitive range and intends to embody modernity.

To know more click here.

Dacia – the disruptive brand that redefines the essential

Dacia designs simple vehicles that have all become market references after their release.

To know more click here.

Lada – the historic brand leader in the Russian market for 50 years on the assault of new horizons

The brand joined the Group in 2017 and is now present in over 20 countries internationally.

To know more click here.

Alpine – the brand at the forefront of sports innovation

Alpine’s ambition is to be both on the racetrack and on the road, to build on its roots while looking to the future.

To know more click here.

Mobilize – the brand looking beyond cars

Mobilize looks beyond cars by offering services around mobility, energy and data.

To know more click here.

To know more click here.

…And at a human level: with a new purpose

Since 1898, the history of the Group has been written by passionate people. Those daring and optimistic talents take mobility further to bring people closer.

This purpose is at the heart of everything: the Group’s values, its strategic plan, its orientations in terms of social and environmental responsibility.

To know more click here.

The Alliance: the best of 3 worlds for a new future

The Renault-Nissan-Mitsubishi Alliance represents 22 years of collaboration and 420,000 employees worldwide. It’s now the 3rd largest global player and becoming the world’s leading generalist manufacturer of electric vehicles.

And to maintain this leading position, the Alliance will invest 23 B€ in the next five years to support its offensive strategy in electrification. With 35 new EV cars in 2030, the Alliance will propose the largest global EV offer, based on the five common EV platforms.

To know more click here.

Present in more than 130 countries, the Group sold 2,696,401 vehicles in 2021.

The Renaulution plan includes 27 new products by 2025. The product offensive is already well underway in 2021 and will continue in 2022…

A look in the rear-view mirror at the must-have products of 2021:

The reveal of the Renault Arkana

A unique concept with a striking design and a range of 100% hybrid engines.

To know more click here.

The reveal of the Dacia Spring

With Spring, Dacia launches the brand’s first 100% electric car.

To know more click here.

The reveal of the Dacia Sandero, Sandero Stepway & Logan:

With these vehicles, Dacia offers a 3rd generation of best-sellers completely renewed

To know more click here.

The reveal of the Dacia Jogger

With this vehicle, Dacia reinvents the 7-seater family car.

To know more click here.

The reveal of the Mobilize Limo

With Limo, Mobilize presents the only car that is not for sale.

To know more click here.

Renault Group is preparing the conditions for Renault to be a 100% electric brand in Europe by 2030. It’s a bold gamble, but it’s in line with history and will enable the Group to meet all the decarbonization targets that have been set and that we have set ourselves.

It’s a bold gamble, but it’s in line with history.

Here are a few highlights of the electric offensive the Group has led over the past year:

New Mégane E-TECH Electric or the symbol of the Group’s electric revolution

It is the first model produced at the Douai plant of the ElectriCity.

To know more click here.

New Renault Kangoo Van E-TECH Electric or a new take on a besteller

With a range of 300km in WLTP cycle, the All-New Renault Kangoo Van E-TECH Electric raises the bar higher than ever before in terms of meeting the every-day needs of professional customers.

To know more click here.

The creation of the ElectriCity division or the largest and most competitive electric vehicle production facility in Europe

Renault’s three manufacturing plants in northern France – Douai, Maubeuge and Ruitz – are joining forces to create Renault ElectriCity. This new electric vehicle production center aims to reach an output of 400,000 electric vehicles a year by 2025 and to bring together an entire ecosystem of suppliers. All this to enable Renault Group and its brands to improve their competitive edge through greater innovation and reduced costs.

To know more click here.

Holding events linked to our electric offensive: eWays

An event launched in 2021 highlighting the historic acceleration of Renault Group’s EV strategy to offer competitive, sustainable & popular electric vehicles.

To know more click here.

The signing of strategic partnerships in the field of electric vehicles batteries

By signing a strategic partnership with Envision AESC to set up a gigafactory in Douai, Renault Group aims to produce of latest technology batteires and thus make electric mobility more accessible in Europe.

Renault Group is going even further to strengthen its competitiveness in the electric vehicle market with an agreement with the French startup Verkor to co-develop and manufacture high-performance batteries.

The combination of these two partnerships with the Renault ElectriCity business unit will lead to the creation of nearly 4,500 direct jobs in France by 2030, and the development of a robust battery manufacturing ecosystem in the heart of Europe.

To know more click here.

What are the different types of electric car battery?

The first electric cars were equipped with heavy lead-acid batteries whose capacity was limited. In the 90s, these were then replaced by nickel-cadmium accumulators with more storage density. But these “Ni-Cd” batteries suffered from memory effect which saw their charging capacity decline over time. Due to the toxicity of cadmium, they are now prohibited. For a time they were replaced by “Ni-MH” nickel-metal hydride batteries, but today all electric cars use lithium-ion technology.

The lithium-ion battery

Invented in the early 1990s, lithium-ion technology rapidly established itself in the world of consumer electronics, and then in the automotive industry. It offers high energy density, very good durability and doesn’t suffer from the memory effect. However, lithium-ion batteries for electric vehicle need to be encased in a sturdy box and monitored by state-of-the-art electronics to prevent overheating or runaway. This is the type of accumulator we find in Renault’s hybrid and electric vehicles.

The solid-state battery

A very promising technology! By replacing the liquid electrolyte, the solid battery becomes more compact and better withstands heat. The solid-state battery therefore offers greater capacity at equal volume, all while also accepting rapid charges. The first mass-market applications, however, are not expected before 2025.

The evolution of electric car batteries

Battery technology has advanced very quickly. As an example, Renault’s ZOE Z.E. 50 uses a battery with the same dimensions as the first ZOE, but whose capacity has grown from 22 to 52 kWh — in other words more than double! Such progress results in an ever-increasing range, now reaching up to 395 kilometers on the WLTP* cycle.

What is a battery made from?

An electric car lithium-ion battery consists of several cells connected to one another, a battery management system (or “BMS”) and a cooling circuit (using air or liquid), all encased within a reinforced waterproof box. The Renault ZOE battery contains no less than 192 cells, for a total capacity of 52 kilowatt hours.

How does the battery work in an electric car?

Each cell of a battery contains two electrodes immersed in a conductive liquid — the electrolyte. When recharging the electric car’s battery, the charger transfers electrons from the positive electrode (anode) to the negative electrode (cathode). Conversely, when the car is in motion, the electric vehicle motor uses the current generated by the flow of electrons leaving the cathode to return to the anode.

Recharging batteries

Whether at home or the office, on the street or the highway, there are many ways to charge your electric vehicle. There are currently more than 200,000 public charging stations in Europe: with 33,000 in Germany, nearly 30,000 in France and almost 25,000 in the United Kingdom. Between 10-15% of these stations offer rapid charging at a high-power output. Then you need to factor in all the stations available in private spaces (at home, work etc.)

How long does it take to charge an electric car?

The electric car charging time is like filling up a water bottle from the faucet: the bigger the bottle or weaker the flow, the longer it takes. At the same charging power, a “big” battery will take longer to charge than a smaller one. And, at the same capacity, it is the power output from the charging station that makes the difference. For example, recovering the equivalent of 100 kilometers of range on a Renault ZOE takes 7.5 hours on a domestic outlet, but just 45 minutes on a public terminal at 22 kilowatts, and only 21 minutes on a 50 kilowatt DC rapid charging station!

Also, one of Renault ZOE’s strengths (since the 2019 model) is its patented Caméléon® charger which supports both direct current (DC) rapid charging at 50 kilowatts and also alternating current (AC) fast charging of up to 22 kilowatts — a power output often found on street-side public charging stations but from which many electric vehicles can’t fully benefit. Thanks to the versatility of its charger, Renault ZOE can get the most power from the connectors and stations most commonly found in both public and private spaces: at home, work, store car park, around the city, on the highway, etc.

What is the lifespan of an electric car battery?

With use and full-to-empty charging cycles, the battery of an electric car eventually wears out, losing its energy capacity. However, this decline is very slow, and it is estimated that an electric vehicle retains on average 75% of its capacity after ten years. In fact, the battery of an electric car is designed to last as long as the vehicle itself.

How much does an electric car battery cost?

To this day, lithium-ion batteries remain an expensive part of the electric vehicle. For example, the battery of a Renault ZOE (with a capacity of 52 kilowatt hours) costs around 8000 euros, depending on the country. However, thanks to technological advances, the cost of electric car batteries keeps falling.

Recycling batteries

An electric car battery contains many valuable materials: lithium, cobalt, nickel, aluminum, etc. But while the channels for recycling these materials already exist, they involve complex and expensive operations that require chemical transformations. It is therefore better to start by finding new, less demanding uses for batteries, and thereby offer them a second life. This is one of the missions of MOBILIZE, which offers innovative energy storage solutions.

Batteries for stationary energy storage

One of the solutions for reusing electric vehicle batteries is as stationary energy storage systems. They can be used to store the electricity produced by wind turbines and photovoltaic panels in order to ensure constant supply when there is no wind or no sun. Such installations can be rolled out for a single house, a building, a factory or even a whole neighborhood. In this way, stationary battery storage could become part of everyday electricity supply.

What is the guarantee for an electric car battery?

For the full purchase of a Renault ZOE, the battery included with the car is then guaranteed for 8 years or 160,000 kilometers, whichever comes first.

Preserving the battery of your electric car in winter

In cold weather, the battery of an electric car becomes less efficient. At the same time, it is under particular strain during this period due to the use of interior heating. So, to maximize the battery’s range in winter, there are a few rules to follow. Firstly, use the pre-conditioning feature when the car is plugged in so that you can heat the interior without drawing from the battery. Secondly, use the “Eco” mode to optimize energy consumption through the intelligent regulation of accelerations, heating and braking. Lastly, adopt eco-driving behavior so as to recover the most energy possible and avoid sudden braking, which uses up a lot of energy. With these techniques, your electric car’s range is optimized.

*WLTP: Worldwide Harmonized Light Vehicles Test Procedure, standardized cycle: 57% urban driving, 25% suburban driving, 18% highway driving.

Copyright : Pagecran

Electromobility: sustainable advantages for the environment

The advent of the electric car is a response to a major challenge: to drastically reduce the amount of carbon dioxide and atmospheric pollutants emitted by modes of transportation. This reduction contributes towards improving air quality and, of course, to the fight against climate change.

Objectives set by the Paris Agreement in particular have led the European Union to draw up legislation on the amount of CO2 that a car may produce when driving. Manufacturers like Renault anticipated this paradigm shift a decade ago by developing vehicles run entirely on electricity. It is, to date, the only automotive technology ensuring zero-emission travel* produced on a large scale. Over its entire life cycle, an electric car like Renault ZOE has a lower carbon footprint than its combustion-powered counterpart by almost 40% on average in Europe**. This percentage varies depending on the energy mix used for the production of energy in its geographic location. Low-carbon energy sources (nuclear, solar, wind) help reduce the carbon footprint made from using an electric vehicle.

Clearly of interest for personal-use vehicles, electric mobility is just as relevant for other modes of transport. Battery-powered buses, electric bicycles and small electric motor vehicles (electric scooters, hoverboards etc.) have spread across cities to provide sustainable transportation alternatives. Electromobility also brings about progress in energy conservation on a wide scale. Carsharing, the innovative service that relieves traffic congestion and offers vehicle access to users when they need, increasingly uses electric vehicles. This new function is perfectly compatible with the principal of recharging, as the car can be topped up between rentals. Plus, shared vehicles are used more frequently than personal cars, which optimizes their life cycle.

An increasing number of municipalities and rural communities are choosing carsharing, where vehicles can also be used for carpooling and journeys on-demand. These new modes of mobility reinforce the choice of transport services available, whether private or public. Often electric, they increase the number of zero-emissions journeys and the resulting benefits for the environment.

The electric vehicle also has a key role in “smart grids” or, in other words, intelligent energy logistics. Thanks to its battery, which is used for real-time energy storage, it promotes the production and use of the lowest carbon electricity possible, with suppliers pledging lower tariffs where green energy is available

The electric car is always improving

Range: the challenge to meet users’ needs

To be fully adopted into the automotive market, the electric car adapts to all types of use. While, at the beginning, its range made it suitable for predominantly short journeys, technological advances now take it much further: like Renault ZOE, which can cover 395 kilometers WLTP on a single charge***. And soon, new models will boast a WLTP range of up to 580 km.

For drivers who are looking for a range similar to that of diesel- and gasoline-powered cars, the current hybrid and plug-in hybrid vehicles like Captur E-TECH Plug-in offer both an electric motor and combustion engine.

Constantly improving charging infrastructure

Numerous motorists are looking to make the move over to electric mobility, and having charging points close to their work, home, roadside or company car park is a real game-changer when it comes to purchasing their first electric vehicle. Governments in multiple countries are developing the installation of charging infrastructure to create constantly-expanding national networks. As an example, the French government has announced the objective of reaching 100,000 public charging stations by the end of 2021, with the German federal government estimating that 70,000 stations are required to effectively serve their electric drivers’ needs.

Electricity supply: an angle to explore

In order to further improve the carbon footprint of electric mobility, electricity supply becomes the focus of attention. This is because, depending on the energy mix of a national grid, the production of one kWh may be significantly less carbon-intensive in a country where renewable energies are favored compared to those which rely principally on thermal power stations to produce electricity. This is the reason why current and planned large-scale developments — in Germany for example — of the wind and solar sectors, gives more weight to the ecological argument in favor of electric vehicles. What’s more, the development of smart grid technology optimizes the charging of electric vehicles, which can be carried out when electricity is the least carbon-intensive.

Challenges for the industry

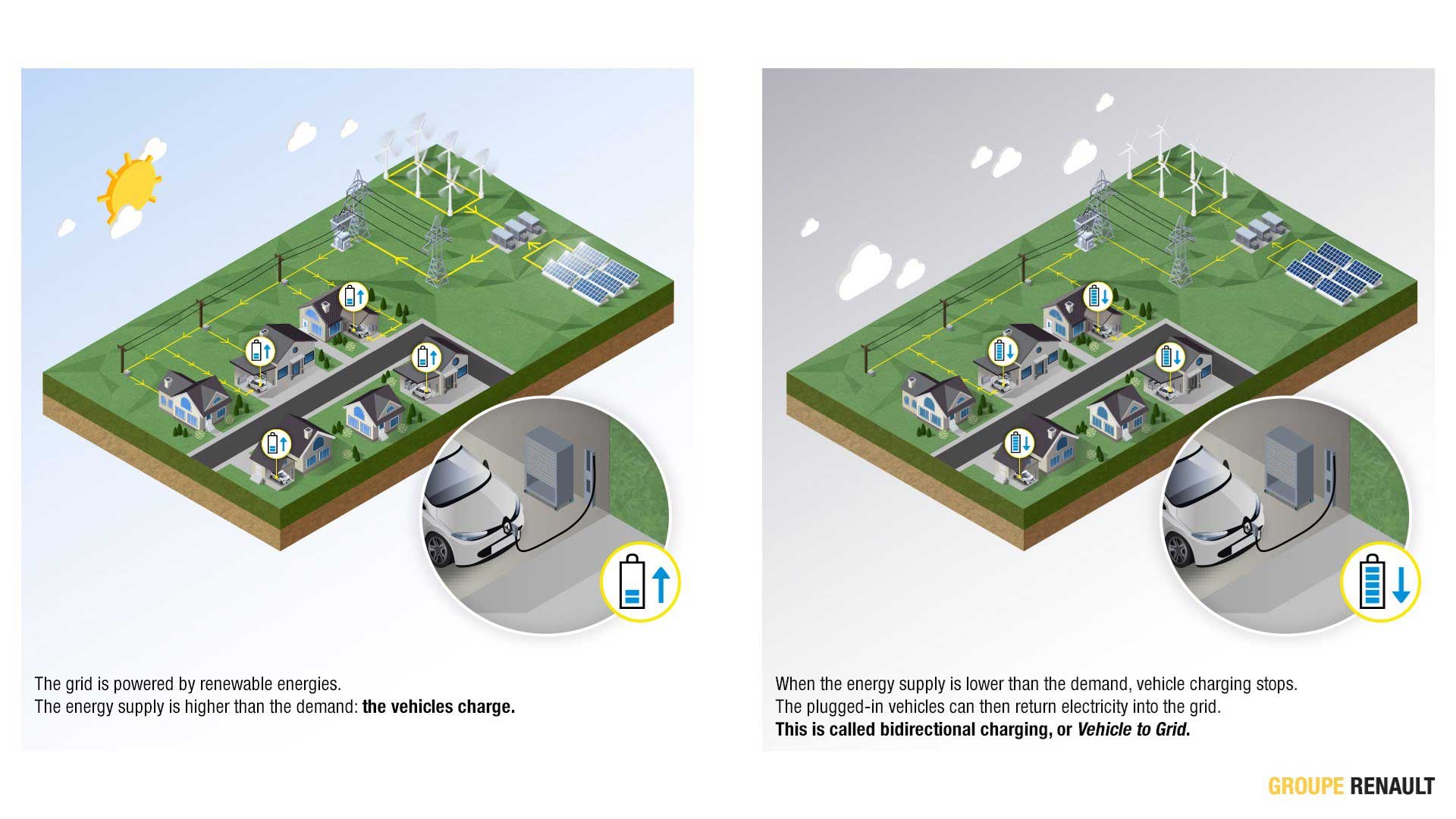

V2G

Also called “bidirectional charging”, and tested by Renault in Utrecht (Netherlands) for example, V2G (vehicle-to-grid) technology looks to be a major innovation in the field of electric cars. It is set to be rolled out on a large scale in the next few years.

Based on the principle of energy storage, it enables the reinjection of electric current from the batteries of vehicles plugged directly into the network. This balances energy supply and demand at all times, especially in the event of intermittent power production — as is the case with wind and solar power. This is a solution to be integrated into future ecodistricts in particular, where renewable energy is produced by wind turbines and solar panels as part of a local distribution channel, but also to larger regions, like cities or islands.

Solar power or electrical induction for wireless charging

What about equipping electric cars with solar panels so that they recharge when stationary, but without needing to be plugged in, as a complement to their high-density battery? This is one of the potential interesting leads being explored at the moment, although it’s early days for the moment.

More mature technically, but requiring additional work in terms of infrastructure, charging via dynamic induction could also increase the range of electric vehicles. Magnetic fields generated under roadway asphalt would be transferred to the car, according to the same principle as the wireless smartphone chargers found on Renault ZOE, for example.

Is Germany the next champion of electromobility?

With its clear political objectives advocating non-polluting vehicles, Germany is a front runner in the electric mobility race. The accelerated roll-out of public charging stations (one charging station per service station in Germany by 2023) and the various purchase aids introduced in recent years herald further growth for a country that already finds itself in the European top spot in terms of electric vehicle sales (in absolute value). Its considerable automotive market gives Germany a strong position among countries driving electric mobility forward.

While the proportion of electric vehicles sold in Germany in 2020 was only 3.7%, this variable is an extremely promising one — doubling in a single year. By comparison, the share of all-electric in new vehicle sales is 7.1% in France, 5.7% in Switzerland and 4.5% in Austria. It could be said, therefore, that it is Europe as a whole, now and moving forwards, which comes out as the champion of electric mobility.

Electromobility: political responses to come

Faced with climate change, the acceleration of the development of electromobility depends on manufacturers like Renault, energy sector bodies and pressure from public authorities. Policies that support the purchase of electric vehicles and the creation of charging infrastructure are a way for governments to reimagine the future of travel. Purchase bonuses, subsidies or tax credits for the installation of charging stations are currently available in France and Germany, for example, following commitments made by public authorities. The future will also see dialogue between manufacturers, consumers and public authorities. In Switzerland, for example, the electromobility roadmap involves 54 organizations working together to ensure that electrified cars represent 15% of cars sold in the country by 2022.

European states and manufacturers are coming to the same conclusion together: the fight against climate change involves a transition to green energies. A transition for which the electric vehicle is one of the most immediate drivers…

* Neither atmospheric emissions of CO2 nor pollutants while driving (excluding wear parts).

** According to the French “Le véhicule électrique dans la transition écologique” (The Electric Vehicle as Part of the Energy Transition), carried out in 2017 for the Foundation for Nature and Mankind.

*** WLTP: Worldwide Harmonised Light Vehicle Test Procedure. The standard WLTP cycle corresponds to 57% of city journeys, 25% of suburban journeys and 18% of motorway journeys.

Copyrights: Jonasre (Adobe Stock), Elexent

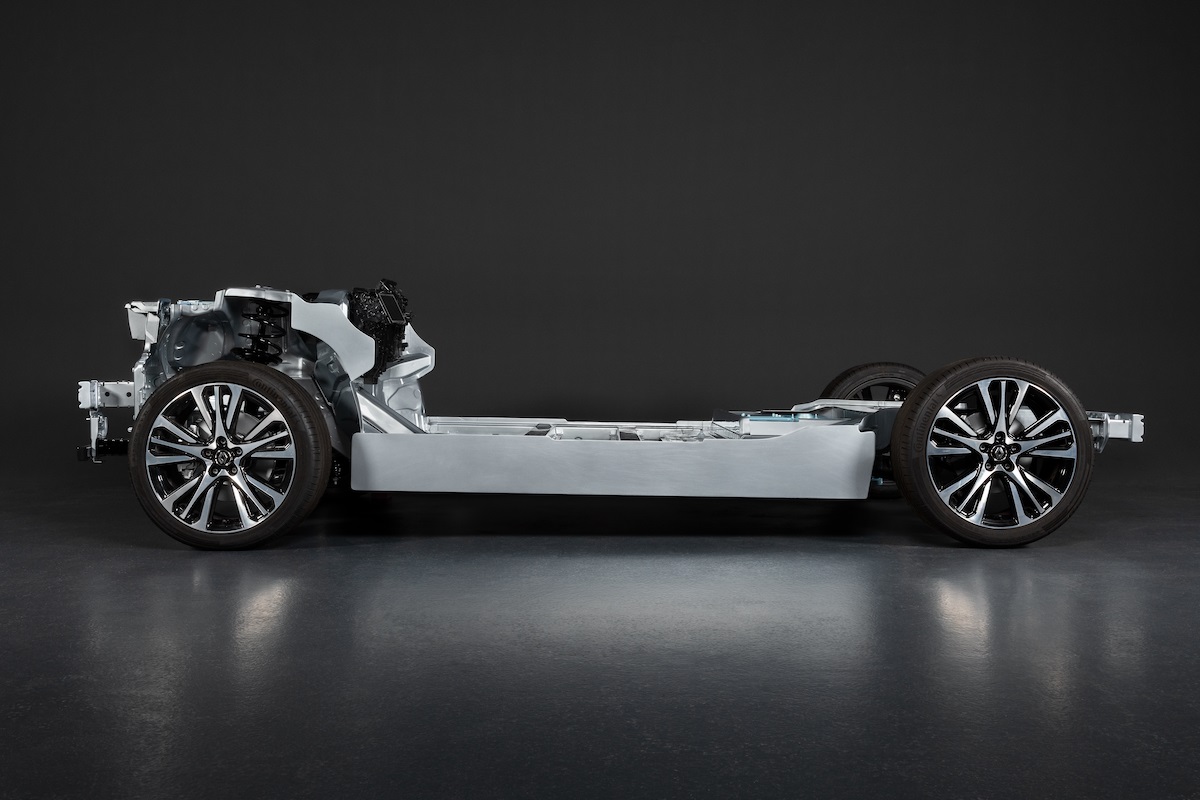

CMF-EV: a strategic platform for the large-scale roll-out of electric cars

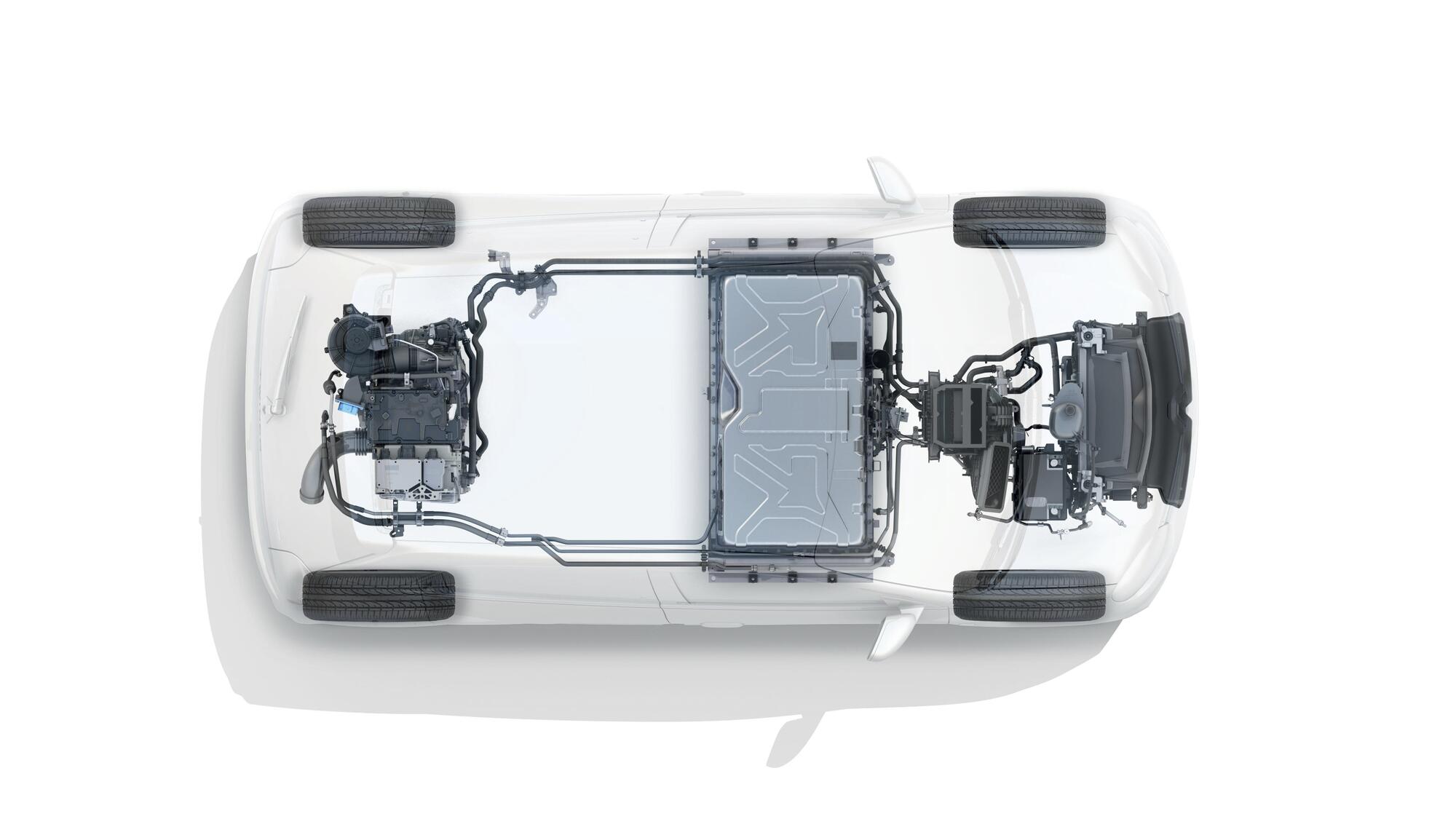

With CMF-EV, the Alliance has chosen a platform dedicated entirely to 100% electric sedans. This is a modular solution for adapting to the numerous future Renault or Nissan brand vehicles.

The platform has been created to integrate — in an optimized manner — all the elements specific to 100% electric powertrain. It therefore hosts a new, high-performance engine and an ultra-thin 60 kW battery. The Mégane eVision show car perfectly illustrates this; promising excellent road handling and a range that allows for multiple uses, including out of town travel.

On an industrial scale, this motor-battery ensemble benefits from close collaborations within the Alliance. Design and sourcing of parts are shared across the two manufacturers, while also making the most of local production. This results in significant large-scale savings, guaranteeing the customer a competitive price. Everything is done in order to make electric travel accessible to everyone.

“The modular nature of the CMF-EV platform, and the collaborations achieved in the creation of the powertrain, result in electric products that are both unique and accessible to as many people as possible.”

Éric Blanchard

Project Director for Electric Systems Projects at Renault Group

An innovative powertrain

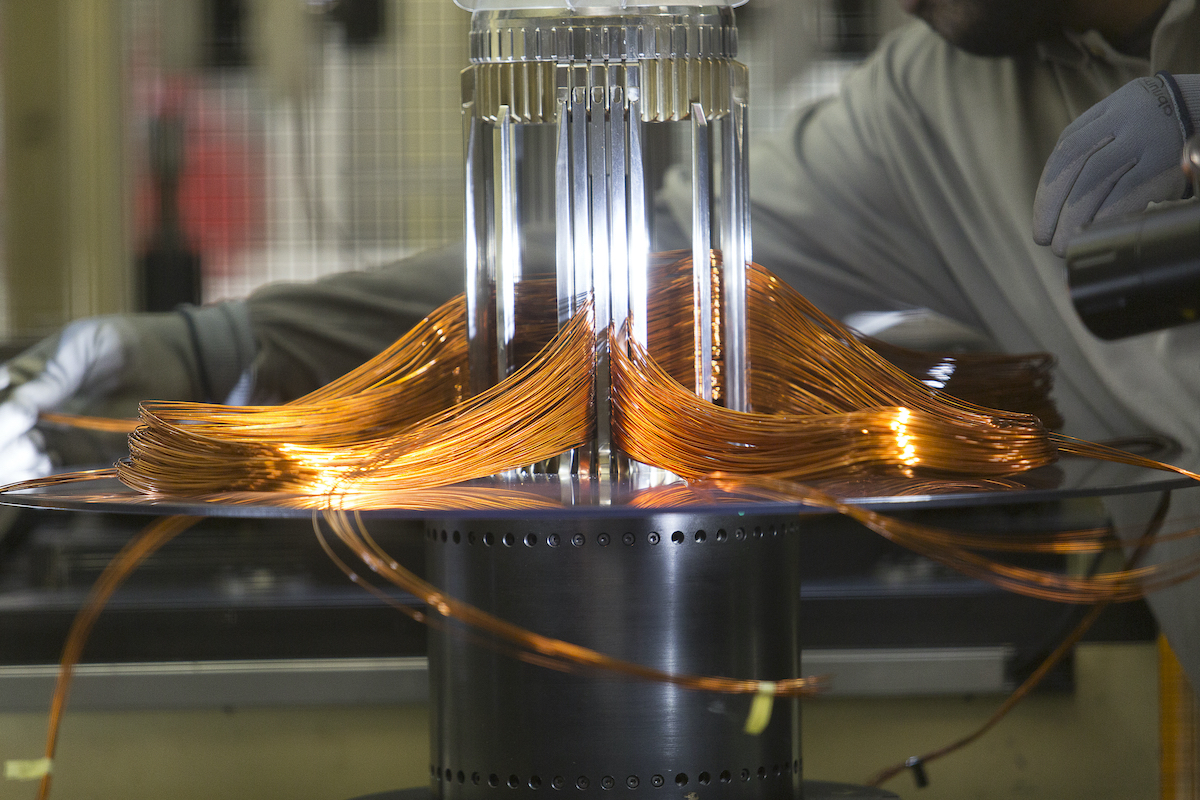

The most high-performance motor from the Renault line

The Mégane eVision’s new powertrain was developed with a focus on efficiency, which goes hand in hand with the vehicle’s range. It is the most powerful Renault engine, all energy types included. Its abilities count 160 kW of power, or 217 horsepower, an acceleration of 0-100 km/h in less than eight seconds, and a torque of 300 Nm. Driving enjoyment is at its highest, especially on a dynamic hatchback like Renault Mégane eVision which is just as comfortable on highways and roads as it is in the city.

The motor benefits from the know-how of the Renault Group engineers right through to its mechanics. It uses the principle of the wound-rotor motor, a veritable expertise and trademark of the French manufacturer, first introduced on Renault ZOE. Contrary to permanent magnets, this technology increases energy efficiency and offers excellent output on the highway. These components, like the copper wiring, are more easily recycled.

In addition, the new 160 kW electric powertrain is cooled via an innovative oil system. The driver can therefore use the accelerator to the maximum, and repeatedly, with no loss of power thanks to a controlled temperature.

“The new 160 kW electric motor is the most powerful of the Renault line. With excellent output, and paired with a high-capacity battery, it combines driving enjoyment with range.”

Olivier Maréchal

Project Manager for Electric Systems Projects at Renault Group

A 60 kWh battery for increased range

As well as its motor, another major quality of Mégane eVision comes from its battery. At 60 kWh, it offers a range of over 450 kilometers on WLTP*, and 280 kilometers on the highway, alongside very short charging times. This is due to water cooling technology, plus increased insulation, which keeps the battery at a low temperature. On a long trip, successive charges are therefore always carried out at a high level of efficiency. According to research by the design team, a journey from London to Newcastle (444 km) on the highway can take a similar overall time as a combustion-powered vehicle. And even in the depths of winter with temperatures below zero, only two recharging breaks of 30 minutes would be required for this journey thanks to the battery’s increased thermal insulation.

The rectangular shape of the battery allows for the integration of a maximum number of cells, thereby increasing its energy density. Its aluminum-reinforced frame contributes to the overall robustness of the casing in the event of an impact, optimizing the weight of the vehicle.

Lastly, fully in keeping with ZOE and Twingo Electric, this battery benefits from a connector which, at every recharge, enables the vehicle to gain the maximum amount of power from every alternative current terminal. This helps to save time, particularly on 22 kW terminals, the most common in urban public spaces. Rapid recharging is also possible at 130 kW on the direct current terminals found along major roads, for example. This makes Mégane eVision the only vehicle in its segment that offers charging efficiency at all power levels, from a domestic socket to a highway charging terminal.

At the heart of CMF-EV: a powertrain that leaves space for interior volume

The design of CMF-EV allows for the integration of an optimal-sized powertrain to ensure onboard comfort and space. The motor compartment contains enough room to store both the new 160 kW electric powertrain, inverter and the air conditioning components (usually found inside the cabin) for even more interior spaciousness.

The shape of the battery also makes it possible to have a flat and low floor. Ceiling height is optimized without any increase to the size of the vehicle, contributing to the overall aerodynamics, an assurance of energy efficiency. On Mégane eVision, the show car close to the future series model, the onboard space is worthy of a vehicle taller and longer by 20 cm. Besides the high levels of performance and range, the qualities of this powertrain — demonstrably designed for 100% electric — thus benefit the entire vehicle.

*WLTP = Worldwide Harmonized Light Vehicles Test Procedure. The WLTP City cycle refers to the urban part of a standardized cycle. The Complete WLTP cycle is the standardized cycle. It consists of 57% urban driving, 25% suburban driving and 18% highway driving.

Copyrights : Jean-Christophe Mounoury

Why is it important to store energy?

At this time of energy transition, storage is a key factor in increasing the proportion of renewable energy sources in the energy mix. One of the major difficulties facing the power grid is the real-time management of the discrepancy between supply and demand, at the risk of compromising the stability and capacity of the domestic grid. This difficulty increases with the incorporation of various energy sources with sporadic production capacities, like wind or solar power. Stationary energy battery storage, wherein energy reserves can be built up and drawn on as needed, acts as a buffer to manage this discrepancy and balance out the network to which it’s connected.

Stationary storage and electric vehicle batteries

Renault Group is committed to sustainable mobility. Going beyond its position as an automobile manufacturer, the group is taking action with the conviction that the electric vehicle is an integral part of the electric ecosystem as a whole. In collaboration with various players in the energy industry, Groupe Renault has developed storage technology using repurposed batteries. When a battery no longer meets the demands of automotive use, it can (before being recycled) be repurposed for large-scale electricity storage. This is a less restrictive and demanding role in terms of energy density and available power. “With a battery, we have much more than a device for mobility. Once the battery’s useful life as an automotive component is over, its residual value is still very high, and it can be used for other applications that are less rigorous, like stationary energy storage. For us it’s the logical next step,” explains Dr. Christophe Dudezert, Program Manager for Energy Services at Renault, and in charge of developing and rolling out the Advanced Battery Storage project in France and Germany.

The residual value of an electric vehicle battery is very high. It can be used for other applications like stationary energy storage, which is the logical next step.

Christophe Dudezert, Program Manager for Energy Services at Renault

Three new projects in France, Germany and the UK

Several experimental initiatives are ongoing, like the one in Porto Santo (Portugal) which uses ZOE and Kangoo Z.E. batteries. Another operating at the SyDEV (the Vendée Departmental Energy and Equipment Union) in La Roche sur Yon (France) is using Kangoo Z.E. batteries. Besides these, three new storage projects have just been launched in Europe.

At the end of 2018, Renault Group announced the launch of the Advanced Battery Storage (ABS) project, a major stationary energy storage system using electric vehicle batteries. It is set to be rolled out to several sites in Europe to reach a capacity of 70 MWh. The George Besse Renault factory in Douai (northern France) now houses the first ABS installation. It has a total capacity of 4.9 MWh, achieved using repurposed batteries and new batteries pending future post-purchase use.

Since the end of November, the ABS project has had a second storage site in Germany. In Elverlingsen, an old coal-fired power plant is home to the country’s first installation of its kind. Developed by Renault Group, The Mobility House and Fenecon, this new storage unit comprises 72 new Renault ZOE batteries with a total capacity of 2.9 MWh.

In West Sussex (UK), the SmartHubs project combines several technologies, including stationary energy storage in containers. The idea is to feed cleaner, cheaper energy into a local electricity grid to power social housing, businesses, transport and more. Designed by Connected Energy, the 360 kWh E-STOR systems each comprise 24 repurposed Kangoo Z.E. batteries. They will be installed on various industrial and commercial sites. Several containers will even be connected to solar panels and electric vehicle chargers to optimize the use of renewable energies and cut costs. The SmartHubs project draws on a total of 1000 repurposed batteries with total capacity of 14.5 MWh, which is enough energy to power 1,695 homes for a whole day.

The development of stationary energy battery storage shows how opportunities for innovation are arising out of today’s environmental challenges. In response to this, MOBILIZE recently signed an agreement with betteries, a German start-up, to design and industrialize innovative energy storage solutions to extend the life of electric vehicle batteries.

Copyrights : Groupe Renault

A country’s electricity grid can source its energy from a fleet of vehicles as long as a large number are plugged in. The electric car therefore becomes a powerful potential energy storage solution. Here are the main principles and advantages of this innovative model.

Why stock electricity in a car?

Compared to primary energy sources, such as coal, gas and oil, electricity remains difficult to store, as there’s only a very short amount of time between its production and consumption. Technological developments can partially alleviate this problem: energy storage in the form of electricity becomes possible through improvements to batteries, especially those in electric cars. This is one of the missions of MOBILIZE, which designs and industrializes innovative energy storage solutions, notably through partnerships – such as the contract recently signed with the start-up betteries.

The rise of renewable energies entails disruptions in the production of electricity. When there isn’t enough wind to turn the turbines, or when the sun doesn’t shine, the energy produced diminishes. Storing energy at periods of high energy production in batteries, in order to then redistribute it during these “off-peak” phases, is a solution to these fluctuations.

This system is particularly interesting from an ecological standpoint: energy storage prevents thermal power stations from having to take the reins in the event of a cutoff in wind or solar power production. With regards to a national or regional electric network, the battery therefore presents a carbon-free solution. In addition, electric cars plugged into the grid offer the possibility of being used as storage; injecting current into the grid during off-peak periods. This technology is known as Vehicle-to-Grid (V2G).

The environmental advantages of energy storage

When thinking about the intelligent use of energy storage, aka the smart grid, V2G could offer multiple ecological advantages. Car connectors and public charging stations are able to exchange data, making it possible to regulate the charging of a vehicle depending on the electricity available across an entire grid.

The smart grid helps to optimize storage depending on the time of day or production levels. The batteries store “clean” energy — in other words low carbon — in order to anticipate these moments of underproduction. They therefore represent a sustainable solution.

V2G: when an electric car becomes an energy storage unit

Like their combustion-powered counterparts, electric cars spend a large part of the day parked. Through the use of “reversible” charging stations in particular, these stationary periods can benefit the electricity grid or the user. The driver arrives at work, parks their car and connects it to the power supply. The car’s integrated smart charging can then choose to fill up the battery when the electricity is low-carbon (and less expensive.) Conversely, when the battery is full, and a peak in consumption occurs, the reversibility of the charging station allows the grid to use a few kilowatts stored in the battery.

Based on this principle, and the existence of the smart grid, battery usage can be part of a strategy for optimizing energy use. The extra energy stored in electric vehicles is used at night when solar power plants do not produce any current. Spikes in demand are also anticipated so that cars plugged into the grid only charge at off-peak times, and that their electricity is available at the right time.

At the heart of smart cities, the V2G principle revolutionizes the use of the electric grid. As a counter to fluctuations in energy production, supply and demand, a car-sharing fleet — in which not all vehicles are used at the same time — becomes a kind of power station. Parked and charged vehicles provide the city with extra kilowatts at opportune times. This type of solution, still awaiting large-scale rollout, is being tested by Renault and its partners in Porto Santo (Portugal), a truly smart island.

The challenges of energy storage in electric cars

A solution for the future of energy conservation and optimized low-carbon electricity distribution, Vehicle-to-Grid still has to overcome some technological and institutional obstacles. Currently in the experimentation phase, V2G will enter the industrialization phase in the years to come, subject to a solution that works for everyone involved. Why not, for example, pay voluntary drivers to let the grid draw from their batteries? This process could completely reinvent the use of the electric car.

V2G works together with increasingly advanced lithium-ion batteries, which can still have several uses after their automotive role (in a “second life”), which extends their life cycle and places them within a truly circular economy, before finally being recycled. These solutions are favored by manufacturers such as Groupe Renault as well as energy specialists — parties who are actively participating in the advent of low-carbon electricity production and mobility as part of their response to the global challenge of reducing CO2 emissions.

Copyrights : Renault Communication

“An electric car? No thanks, especially if it means hanging around while it charges.” quips Pimpmyride1 on an on-line auto forum, to which Supercar-59 adds, “EVs lack punch!”. It is time these misconceptions are done away with. Indeed, the time when EVs had to be plugged in every 100km is over. Yes, there are more and more charging stations (on public roads, but also in businesses and at homes). No, electric cars do not suffer more from the cold than combustion engines. And, yes, the carbon footprint of an electric vehicle is actually lower than that of a combustion motor over its entire life cycle. Not to forget that it’s a joy to drive. The difference is immediately perceptible: electric cars offer a fast and quiet start, with instant torque needed for clean and powerful acceleration. Being behind the wheel of an electric car is like crouching into a tuck to swiftly speed down a ski slope. So yes, EVs do pack a punch.

Because e-mobility comes with all these advantages – and then some – it is quite clearly a solution for the future. On one condition: that it is supported by a responsible and sustainable value chain.

1. Renault Group: a pioneering vision

Still have doubts? We don’t.

Generations of engineers have spent the past 15 years developing our EV models, while procurement teams have been trained up over the past 10 years and our dealerships know EV inside out: everyone is pitch perfect and ready to go. In fact, all our European manufacturing sites are converting over into EV production plants. We have believed in the future of electric vehicles for more than a decade. Ten years during which we have boldly designed models for any use imaginable.

And when look back over our past in the rear-view mirror, there’s much to be proud of:

- more than 400,000 customers worldwide

- more than 10 billion e-km travelled

- 30,000 RG employees with specific EV training

We are stepping up efforts to win over those who still need a bit more convincing: by bringing innovation to our customers, designing increasingly efficient and accessible electric vehicles, and developing large-scale, sustainable electrical ecosystems.

2. Safe, powerful and affordable batteries

Batteries are the beating heart of electric cars and are the focal point for our engineering teams.

To optimize both their cost and performance, we will adopt a new approach in 2024: standardization.

Standardization in terms of the physical structure because all our batteries will be made using only two cell formats, but also in terms of chemistry since we use NMC type lithium-ion batteries.

If you’re still not entirely up to speed with the ins and outs of Li-NMC technology (NMC, a.k.a ‘Nickel, Manganese, Cobalt’), here’s a quick video to help:

The two cell formats are as follows:

- an affordable design with excellent cost-to-battery-life ratio for A- and B-segment models, made in the ElectriCity Gigafactory (that we will discuss later);

- and a high-performance solution with fast-charging capacity for C-segment and sports vehicles.

Curious to know more about how batteries work? Find out everything you need to know to make a good impression.

Another major topic when it comes to batteries is safety. In this regard, we can confidently say that Renault has set industry-wide standards, with thermal runaway not once being reported over the last ten years.

This is partly thanks to the roll out of Renault’s own ‘Battery Management System’ – a battery monitoring system fitted on our vehicles – that prevents rising battery temperatures and thus reduces the risk of internal fire. It is also thanks to innovative security measures such as the Fireman Access – an incredibly effective way for rescue teams to quickly and permanently extinguish battery fires caused by an external fire. Not to forget the ‘Rescue Code’ (a QR code located on the wind shield) that gives fire-fighters easy access to documentation on the battery’s technical specs.

To find out more, (re)discover:

- Episode 2 of keynotes on batteries

- The press release “Renault Group places France at the heart of its industrial strategy for EV batteries”

3. A state-of-the-art powertrain

Now let’s talk E-engines. With ten years of experience in E-engine technology, we harness the power of electrically excited synchronous motors. Why is that? Mainly because it has key advantages such as excellent power yield (better than permanent-magnet synchronous motors) and it doesn’t incorporate rare earth metals (thus making it cheaper with large-scale production).

Proven technology with exciting prospects: the next generation of electrically excited synchronous motors will be able to handle the higher 800V power supply, and will incorporate state-of-the-art technology making it safer, smaller, and more efficient.

As the adage goes, a picture is worth a thousand words: here is our upcoming electrically excited synchronous motor:

As for power electronics – still as part of our quest for greater efficiency – we are working on a new strategy with three primary objectives: reduce electricity loss, cost, and size. This will be achieved thanks to our ‘One Box’ concept whereby all power electronics (reducer, DC-to-DC converter, on-board charger) will be mounted inside a single unit.

Another strategic goal is to vertically integrate power electronics to have greater control over both costs and the value chain. More specifically, we will start off by developing advanced expertise in electronics design, followed by a second phase where we will internalize printed circuit board assembly.

We have been discussing innovation in both electric motors and power electronics. Two essential parts of a much larger ensemble: the vehicle’s overall powertrain. We are working on a fully integrated power train with the electrically excited synchronous motor, reducer, and One Box power electronics all combined into a 3-in-1 system.

45% less electricity loss

(for a 20km increase in range)

30% lower costs

40% smallergiving more room for passengers

We will take things yet another step further with the addition of disruptive technology: the axial flux motor. Developed in partnership with French start-up Whylot, it will boast numerous advantages for our hybrid vehicles, such as a 5% cost reduction, and CO2 gains of up to 2.5 grams. Benefits that will trickle over into our EV range.

This investment will see us become the leading automotive parts supplier for these electric motors as of 2025.

4. The best tech around on our platforms

To accommodate high-performance, bespoke batteries and a particularly efficient and compact power train: we use state-of-the-art EV platforms. Platforms that house each piece of tech you have just glimpsed.

Platforms that come in one of two versions:

- ‘CMF-EV’ for C/D segment vehicles, such as the All-New Megane E-TECH Electric, for even more driving pleasure

- ‘CMF-BEV’ for segment B vehicles, such as upcoming Electric Renault 5, for the best price-to-performance ratio possible.

Let’s take a closer look at each platforms to better grasp how they make for a much smoother drive.

CMF-EV platform:

- Advantage #1: Autonomy

Vehicles based on the CMF-EV platform will boast a WLTP range of up to 580 km, thanks to optimized efficiency and energy management.

Just how have we achieved that? We have worked on reducing friction and weight (-100kg compared to the closest competitor model) and improving thermal management (+5% range in cold weather), in addition to incorporating our battery technology (e.g., NMC technology).

- Advantage #2: Comfort and driving pleasure

Gliding through the countryside behind the wheel of an electric car may already seem like a truly enjoyable experience. But now imaging gliding along those same roads in a church-like silence. This is the principle behind the ‘smart cocoon effect’ which harnesses the power of patented soundproofing foam placed between the battery and the floor plate to reduce in-car noise by 50% compared to current models. The foam also creates a sound barrier against the wind and road.

The passenger compartment is quitter, but also roomier. Our ‘smart packaging’ means more leg room and more luggage space, putting it on par with larger vehicles. It also features excellent ergonomics with a particularly comfortable sitting position and a comfortable rear leg room. Why is that? Simply put, all powertrain components are placed in the front end, thereby helping to give more room and reduce both overall weight and cost. Not to forget that the heating, ventilation, and air conditioning system is mounted under the bonnet, which means the dashboard isn’t as deep giving more room for passengers. Lastly, the battery pack, among the slimmest for the specific drive range, leaves more room between the floor plate and roof.

One last point on ‘comfort’, our vehicles are now more enjoyable to drive thanks to optimised on-road dynamics:

- the very low steering ratio means faster response, better handling, and greater agility

- the multi-link rear suspension means better road-type adaptation and wheel alignment

- the battery’s position in the vehicle makes for a lower centre of gravity and ideal weight distribution

CMF-BEV platform

- Advantage #1: Cost

The first and perhaps most anticipated advantage of our second platform is the 33% reduction in the overall cost of vehicles (compared to ZOE), which has been made possible thanks to:

– an interchangeable battery module for cross-platform use

– a new and smaller powertrain for cheaper output at 100kWh

– the use of ‘non-EV’ CMF-B platform components on the platform and upper body, which means a significant drop in the costs of parts

- Advantage #2: Versatility

The remarkable features of this platform are achieved without compromising on its design: the platform has been optimized to be highly versatile and easy to adapt to all sorts of vehicles, including our most iconic models.

5. Renault ElectriCity: the best industry-side EV solutions

State-of-the-art platforms, batteries, and power trains for EV models that are more efficient than ever. As we put our EV vision into motion, we strive for greatness in the Renault ElectriCity. A unique industrial hub like no other in Europe and a centre for Alliance excellence that brings together three of our facilities: Douai, Maubeuge, and Ruitz. It also incorporates an entire ecosystem of contractors – including an EV battery ‘Gigafactory’.

Why is the ‘EV Hub’ in the north of France? Because in manufacturing out of such a strategic location – in the heart of Europe – we will reduce the cost of logistics for foreign customers.

The project is driven by two main ambitions: stimulate innovation and efficiency; and reduce production costs by building on Renault’s industrial expertise, in particular by leveraging the power of flexible assembly lines that can produce two platforms and by pooling together indirect functions across the three plants.

With a projected output of 400,000 vehicles per year, Renault ElectriCity will be the leading and most competitive production centre in Europe! The life blood of our ambitious project, 700 direct jobs that will be created by 2025, and spread across the three factories in Maubeuge, Douai, and Ruitz. In addition, a tertiary education centre will be set up in the near future to provide training programmes that are adapted to the changing automotive market and to help further research.

Find out all there is to know on the subject:

6. Batteries that will last many lifetimes

So far, we have discussed the driving pleasure, performance, and range of our electric vehicles. Now comes the issue of sustainability; in particular, when it comes to batteries. Once again, we have good news that will shake up a few preconceived ideas: batteries outlive the cars they power. Because, just like cats, batteries have many lives. And we will be there at every step of the way – in other words, throughout their whole ‘life cycle’ – to make sure our vehicles are as profitable and affordable as possible. Let’s explain how.

1st life:

What purpose does a battery serve in an electric car? First and foremost, to drive the car. But did you know that during a battery’s first life – while it’s still in a car – it can also be used to provide cities, buildings, and homes with electricity during peak power consumption? This is known as vehicle-to-grid (V2G). Grid operators are ready and willing to pay for services provided by car batteries that can reinject energy back into the grid for 8 hours a day: up to 400€ per year and per car.

In this regard, Renault is ahead of the curve and is developing large-scale V2G services ready for 2024, including a fully integrated Europe-wide service and a proprietary solution for bi-directional AC charging (less expensive than its DC equivalent). In addition to its smart off-peak charging solution, Renault will be rolling out V2G services in the near future.

Learn all there is to know about V2G in under 2 minutes:

2nd life:

Our batteries are built to last about ten years. But even after having powered your car for all those years, they still have energy to burn during retirement (a.k.a. ‘2nd life’). Their new purpose in life: to provide electricity to a less ‘energy intensive’ system or to serve as a stationary storage unit. Here again, Renault is shaping a market that will boost the residual value of batteries. How? By developing an industrial ecosystem that is like no other in Europe: a used battery collection network, a re-factory in Flins, and a range of industrial partnerships that cover the wide selection of new purposes for used batteries.

Aside from the ecological argument behind reusing second-hand batteries for stationary energy storage, it also helps drive further value creation. Renault, through Mobilize, will also work with Argus – among others – to widely promote the residual value of EV batteries, so that it can be properly reflected in the sale and purchase of used vehicles. Residual value can reach €500 per car.

Recycling:

When a battery reaches the end of its 2nd ‘plentiful’ life (between 5 and 10 years), it then enters the world of recycling. The ‘downstream’ processes of the recycling industry are already well mastered, with the collection of batteries and their dismantling in Flins. What if tomorrow we could go further by reconstructing new batteries from end-of-life batteries? This is the ambition we have set ourselves with other major industrial groups, Veolia and Solvay. By uniting our forces, we will extract, separate, and purify metals such as lithium, nickel, or cobalt, so that they can be reused in new batteries. That brings us back to where we started.

Here, too, beyond the obvious ecological importance, we will be able to leverage the value of this process: it will not only allow us to recover more valuable materials, but also halve the net cost of recycling by 2030.

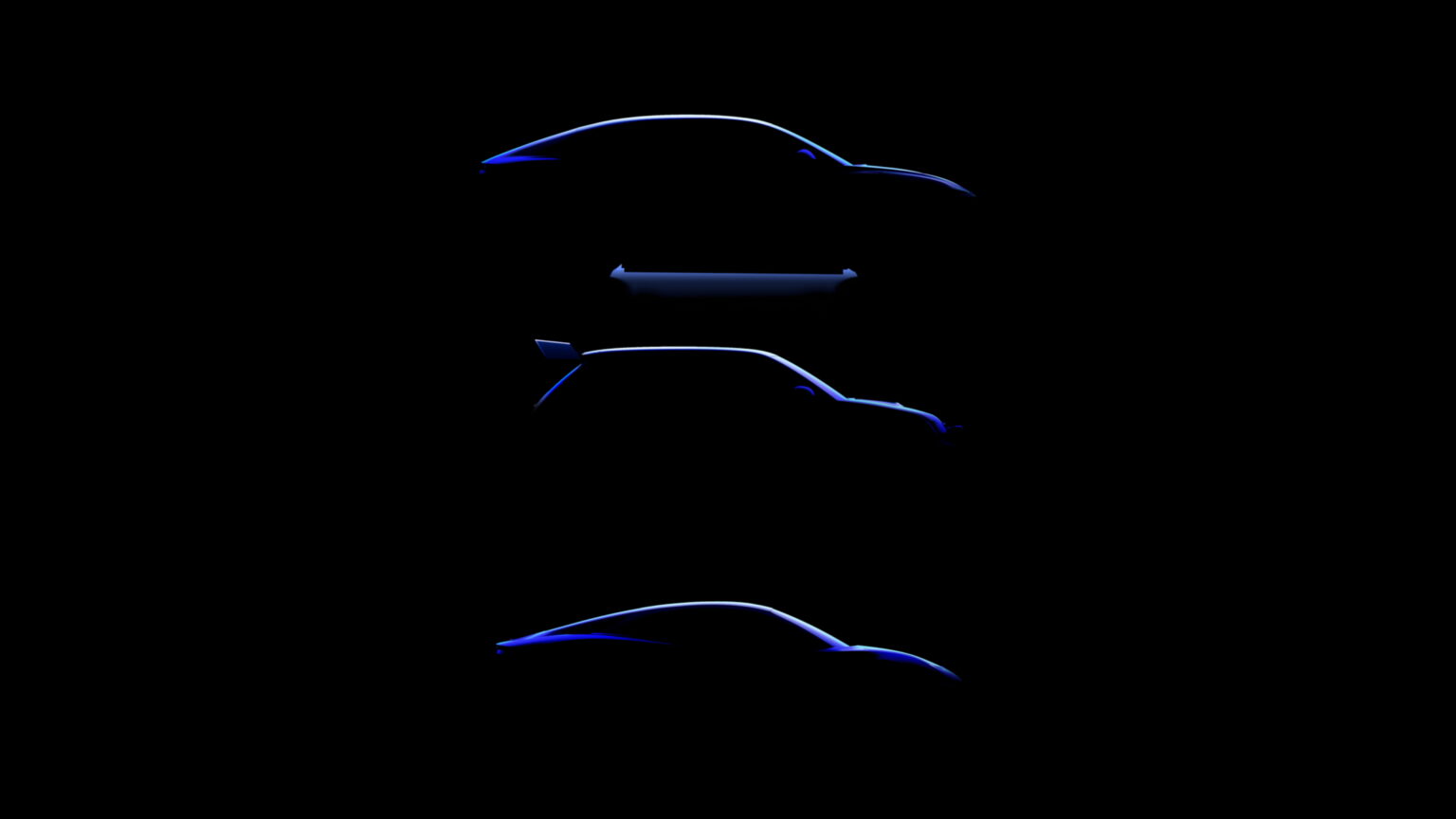

7. The future is electric: 10 new models join the ranks

It has been made quite clear that we are already well positioned for the future of electric mobility. In fact, our family is set to grow in the next five years with 10 new models.

You may have already seen the show cars that will give rise to our first two models: Megane eVision, a powerful EV sedan with a bold design and leveraging everything the CMF-EV modular platform has to offer; the legendary Renault 5 EV, built on the CMF-BEV platform, will bring together an iconic design with a powerful yet affordable vehicle. Megane eVision will become the All-New Megane E-TECH Electric in just a few months, and the R5 EV will hit the market in 2023.

Seven more models from the Alpine and Renault ranges will round out the new additions, with – you have probably already guessed it – a new take on one of our legendary models. While you will need to be patient before you get to sit behind the wheel of one of our new models, know that they will all share a defining feature: excellent price-to-performance ratio without compromising on design.

The All-new Mégane E-TECH Electric will soon be accompanied by another model on the CMF-EV platform

After the R5, another Renault icon will return in a 100% electric version on the CMF-BEV platform

Alpine’s 100% electric “Dream Garage” will soon be a reality

“In the nineties, electro music was a big hit in France. It gave birth to the ‘French Touch’ with iconic bands. Electro Pop is the ‘Renault touch’ of electrification. We aim for iconic cars, making it to the top of the charts.”

Luca de Meo, CEO Renault Group

Beyond accessibility, and innovative technology and design, we endeavour for our future range to be the greenest mix of cars on the European market by 2025, with up to 90% of Renault sales coming from EV models. The future will be electric, and it will be clean.